| MANUAL CHOKE VALVE

The choke valve, a main Description of Christmas tree, is design to control production rate of the oil well, with working pressure up to 10000psi. Choke valves can be classified as follows: adjustable choke valves and positive choke valves. By rotating hand wheel to drive the stem, the adjustable choke valve is designed to adjust the effective area available for the flow to accomplish control of production rate. The positive choke valve is design to accomplish control of production rate by changing flow beans.

Features:

1. The coupling nut used for connecting the bonnet and body allows fast make-up and break-out.

2. Stem tip and bean adaptor are fabricated from special carbide alloys for corrosion and abrasion resistance.

3. Indicator lens with scale marks allows the operator to know stem’s position and actual orifice area.

4. Turn hand wheel counter-clockwise and the valve will open; turn hand wheel clockwise and the valve will close.

| |

|

|

|

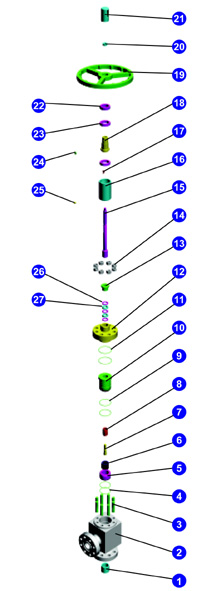

Parts List

Item |

Description |

Qty |

Material |

Remark |

*1 |

Bushing |

1 |

FKM |

|

2 |

Body |

1 |

4130 |

|

3 |

Bonnet Stud |

8 |

4130 |

|

*4 |

O-Ring |

1 |

NBR |

|

5 |

Seat Bushing |

1 |

4130 |

|

*6 |

Seat |

1 |

YG8 |

|

*7 |

Stem Adaptor |

1 |

NBR |

|

*8 |

Valve Core |

1 |

YG8 |

|

*9 |

O-Ring |

2 |

NBR |

|

10 |

Packing Box |

1 |

4130 |

|

*11 |

O-Ring |

2 |

NBR |

|

12 |

Bonnet |

1 |

4130 |

|

13 |

Packing Gland |

1 |

4130 |

|

14 |

Bonnet Nut |

8 |

5140 |

|

*15 |

Stem |

1 |

410 |

|

16 |

Screw Housing |

1 |

5140 |

|

17 |

Saddle Key |

1 |

1045 |

|

18 |

Stem Screw |

1 |

4130 |

|

19 |

Handwheel |

1 |

1035 |

|

20 |

Spacer |

1 |

410 |

|

21 |

Stem Protector |

1 |

1035 |

|

*22 |

Bearing Gland |

1 |

5140 |

|

*23 |

Bearing |

2 |

Assy. |

|

24 |

Flat Key |

1 |

1035 |

|

*25 |

Grease Cup |

1 |

Assy. |

|

*26 |

Packing Ring |

2 |

410 |

|

*27 |

Packing |

5 |

NBR |

|

*Major Repair------─ One Each For One Year’s Service

HYDRAULIC CHOKE VALVE

The hydraulic choke valve is used to be matched with manifold and other assemblies, which is applicable for flow-rate adjustment, that is, to raise or reduce the valve core location is help for alternation of flow-way cross-area and flow-rate control.

Main technological parameters

Rated pressure:2000~15000psi

Working temperature:P U

Working medium :petroleum & natural gas.

Parts List

Item |

Description |

Qty |

Material |

Remark |

1 |

Body |

1 |

4130 |

|

*2 |

Bushing |

1 |

FKM |

|

*3 |

Seat Bushing |

1 |

4130 |

|

*4 |

O-Ring |

1 |

NBR |

|

*5 |

Seat |

1 |

YG8 |

|

6 |

Stop Nut |

1 |

1045 |

|

*7 |

Valve Core |

1 |

YG8 |

|

8 |

Lower Diversion Bushing |

1 |

410 |

|

9 |

Upper Diversion Bushing |

1 |

410 |

|

*10 |

Stem |

1 |

410 |

|

*11 |

O-Ring |

1 |

NBR |

|

*12 |

O-Ring |

2 |

NBR |

|

13 |

Bonnet |

1 |

4130 |

|

14 |

Cylinder |

1 |

4130 |

|

*15 |

Cylinder Adapter |

2 |

4130 |

|

*16 |

O-Ring |

2 |

NBR |

|

*17 |

O-Ring |

2 |

NBR |

|

*18 |

O-Ring |

2 |

NBR |

|

*19 |

Piston |

1 |

1045 |

|

20 |

Cylinder Cover |

1 |

4130 |

|

21 |

Circlip |

1 |

1566 |

|

22 |

Screw |

4 |

4130 |

|

23 |

Washer |

1 |

4130 |

|

*24 |

O-Ring |

2 |

NBR |

|

25 |

Bonnet Nut |

8 |

5140 |

|

26 |

Packing Gland |

1 |

5140 |

|

27 |

Bonnet Stud |

8 |

4130 |

|

*28 |

Packing Ring |

2 |

410 |

|

*29 |

Stem Lip Packing |

5 |

NBR |

|

*Major Repair------─ One Each For One Year’s Service

ADJUSTABLE AND POSITIVE CHOKE VALVE

The adjustable and positive choke valves are designed for reliable flow control and maximum wear life, The choke valves are available in flanged or threaded ends in standard bore sizes form 1-13/16” thru 4-1/16”,in working pressures of 2000 psi through 10000 psi.

|

|

Adjustable Choke Valves |

Positive Choke Valves |

|